3D printer helps launch new line of boats

An Indiana machine builder helped a boat company simplify and speed the process of producing the tooling used to make a fibreglass boat mould.

Typically, a tool ─ referred to as a plug ─ is fabricated from one of a variety of materials, glassed over, faired, and mirror-finished.

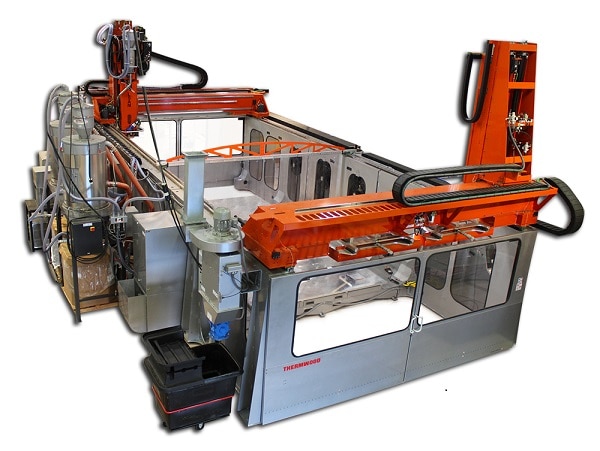

White River Marine Group (WRMG) discovered 3D printing may offer a better way to build tooling. The Springfield, Mo., boatbuilder credits Thermwood Corp’s Large Scale Additive Manufacturing (LSAM) machine for helping it achieve its goals.

WRMG, the marine manufacturing arm of Bass Pro Shops, worked with Thermwood to custom-print the tooling used to make the mould for the hull of its new TAHOE T16, a 16-foot fibreglass craft.

Reportedly, the tooling represents the first time additive manufacturing has been used for boat production at this scale. It led to greater efficiency during planning, designing, and construction of the T16, according to a press release.

The process

Thermwood printed the master pattern for the boat hull at its development/demonstration labs (watch the video) in Dale, Ind. The pattern was printed in six sections from 20-percent-carbon-fibre-filled ABS supplied by Techmer PM, Clinton, Tenn.

Next, the joints between the pieces were machined, pinned, and bonded together. Then the assembled tooling was machined to final size and shape. The entire process required only 10 days.

After printing and machining, the tool was sent to WRMG, where the boatbuilder applied a proprietary coating, and then sanded and polished it.

Speeding up the process

The Thermwood LSAM has a 10- by 20-foot work envelope and combines additive manufacturing capabilities and routing.

Thermwood said that a tool like the one for the TAHOE could be produced in even less time with current technology. Using Thermwood’s Vertical Layer Printing process, which wasn’t available at the time, the tooling could be printed as one piece in just over two days, eliminating the need to machine between sections and the bonding process. This, the machine builder estimates, would cut print time by nearly 50 percent.

“Master patterns like the TAHOE’s are used to make moulds for long-run production jobs and require making multiple moulds. For larger boats or lower production volumes, it may be possible to print the mould itself rather than a pattern from which multiple moulds are produced,” said a representative from Thermwood.

The company recently announced that it had successfully printed a 7-ft-long, 1/7th-scale model of a yacht hull mould using Vertical Layer Printing.

Click here to learn more about Thermwood’s LSAM technology.

White River Marine Group’s TAHOE T16 fibreglass boat.

Story by Don Nelson, The Additive Report